Contact Form

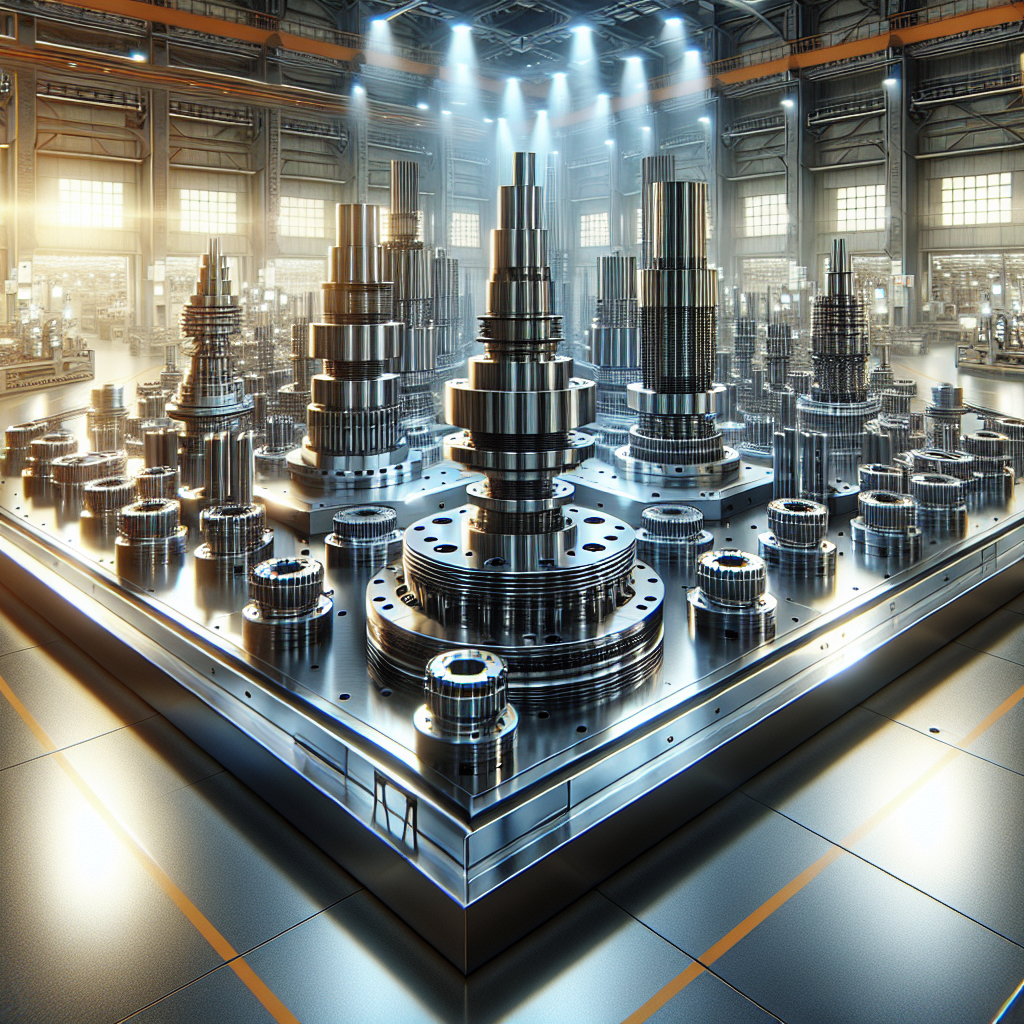

Thank you for considering Petro Tajhiz Company as your trusted partner in sourcing high-quality chemical and steel raw materials. Our commitment to excellence, innovation, and customer satisfaction drives everything we do. Whether you’re in the oil & gas, defense, power, petrochemical, or aerospace industry, we are here to cater to your unique needs with bespoke solutions tailored to your requirements. Reach out to us today to experience the Petro Tajhiz difference firsthand. Your success is our success, and together, we’ll achieve new heights in industry standards.

390 Bay St, Toronto, ON M5H 2Y2

Phone: (1) 647 697 9216

Fax: (1) 647 697 9216

E-Mail: info@thepetrotajhiz.com

Web: https://thepetrotajhiz.com/

Reviews

There are no reviews yet.