From Factory to Foundation: Selecting Eco-Friendly Steel for Green Projects

Introduction

In an era where environmental sustainability has transitioned from a corporate buzzword to an imperative business strategy, the steel industry stands at a critical crossroads. As one of the world’s most carbon-intensive sectors—accounting for approximately 7-9% of global CO2 emissions according to the World Steel Association [1]—the industry faces mounting pressure to reinvent itself through eco-friendly practices and materials. This transformation isn’t merely about regulatory compliance; it represents a fundamental shift in how we conceptualize, produce, and utilize one of civilization’s most essential building materials.

Sustainable steel solutions encompass a range of innovative approaches, from the development of low-carbon production methods to the creation of specialized eco-friendly steel grades designed for specific applications. These advancements not only reduce environmental impact but often enhance performance characteristics, creating a compelling case for their adoption across industries ranging from construction to renewable energy infrastructure.

This article explores the landscape of sustainable steel solutions, with particular focus on eco-friendly steel grades that are revolutionizing how industries approach environmental consciousness without compromising on structural integrity or performance.

Understanding Eco-Friendly Steel Grades

What Makes Steel “Eco-Friendly”?

Steel’s environmental impact is primarily determined by three factors: its production process, its composition, and its lifecycle performance. Eco-friendly steel grades excel in at least one—and ideally all—of these dimensions:

1.Production Process: Steel manufactured using electric arc furnaces (EAF) typically generates 75% less CO2 than traditional blast furnace methods [2]. The most sustainable grades utilize high percentages of recycled content, renewable energy in production, and innovative technologies like hydrogen reduction.

2.Composition: Advanced high-strength steels (AHSS) and ultra-high-strength steels (UHSS) allow for thinner, lighter components that require less material while maintaining or improving performance. According to research published in the Journal of Cleaner Production, using AHSS can reduce a vehicle’s weight by up to 25%, significantly improving fuel efficiency [3].

3.Lifecycle Performance: Truly eco-friendly steel grades offer extended durability, corrosion resistance, and recyclability. Weather-resistant grades like ASTM A588 can eliminate the need for protective coatings and their associated environmental impacts [4].

Key Eco-Friendly Steel Grades and Their Applications

High-Strength Low-Alloy (HSLA) Steels

HSLA steels represent one of the most widely adopted eco-friendly steel categories. These grades achieve superior strength through microalloying elements like niobium, vanadium, and titanium, typically in concentrations below 0.1% [5]. This microstructural engineering allows for:

•20-30% weight reduction compared to conventional carbon steels

•Improved weldability and formability

•Enhanced corrosion resistance

Applications include:

•Automotive structural components

•Pipeline transport systems

•Bridge construction

•Wind turbine towers

A landmark study by the American Institute of Steel Construction demonstrated that HSLA steel used in bridge construction reduced material requirements by 27% while extending service life by an estimated 30% compared to conventional grades [6].

Advanced High-Strength Steels (AHSS)

AHSS grades represent the cutting edge of metallurgical innovation, offering exceptional strength-to-weight ratios through sophisticated microstructural design. These steels typically achieve tensile strengths exceeding 780 MPa through carefully controlled cooling processes and precise alloying [7].

Key varieties include:

•Dual Phase (DP) steels

•Transformation-Induced Plasticity (TRIP) steels

•Complex Phase (CP) steels

•Martensitic steels

The automotive industry has been particularly aggressive in adopting AHSS, with the average vehicle now containing over 200 kg of these advanced grades. According to WorldAutoSteel, this transition has reduced vehicle body structure weight by up to 25% while improving crash performance [8].

Weathering Steels

Weathering steels like ASTM A588 and A242 contain copper, chromium, and nickel alloying elements that form a protective patina when exposed to the atmosphere. This self-protecting surface eliminates the need for paint or galvanizing, reducing both initial environmental impact and maintenance requirements [9].

The most notable application of weathering steel is in architectural and infrastructure projects, where its distinctive appearance and minimal maintenance requirements offer both aesthetic and environmental benefits. The iconic Barclays Center in Brooklyn features a façade made entirely of weathering steel panels, eliminating thousands of gallons of paint and protective coatings over the structure’s lifetime [10].

Powering Renewable Dreams: Sustainable Steel in Energy Infrastructure

Sustainable steel isn’t just about strength; it’s about promise. From wind turbine towers to solar panel supports, eco-friendly steel grades are the backbone of renewable energy projects. For instance, wind turbine towers crafted with sustainable steel exhibit superior fatigue resistance, ensuring longevity and reliability in the face of nature’s whims.

Wind Energy Applications

The wind energy sector represents one of the most demanding applications for sustainable steel, requiring materials that can withstand decades of dynamic loading while minimizing environmental impact. Modern wind turbine towers typically stand 80-120 meters tall and must support nacelles weighing up to 300 tons while enduring millions of stress cycles [11].

High-strength low-alloy (HSLA) steels have emerged as the material of choice for these applications, offering:

•Fatigue resistance exceeding 20 million cycles at critical stress points

•Yield strengths of 355-460 MPa

•Excellent weldability for on-site assembly

•Reduced material requirements through optimized thickness

A 2023 lifecycle assessment published in the International Journal of Life Cycle Assessment found that using HSLA steel in wind turbine towers reduced embodied carbon by 18% compared to conventional grades while extending expected service life by 5-7 years [12]. This improvement is particularly significant given that the steel tower represents approximately 26% of a wind turbine’s total carbon footprint.

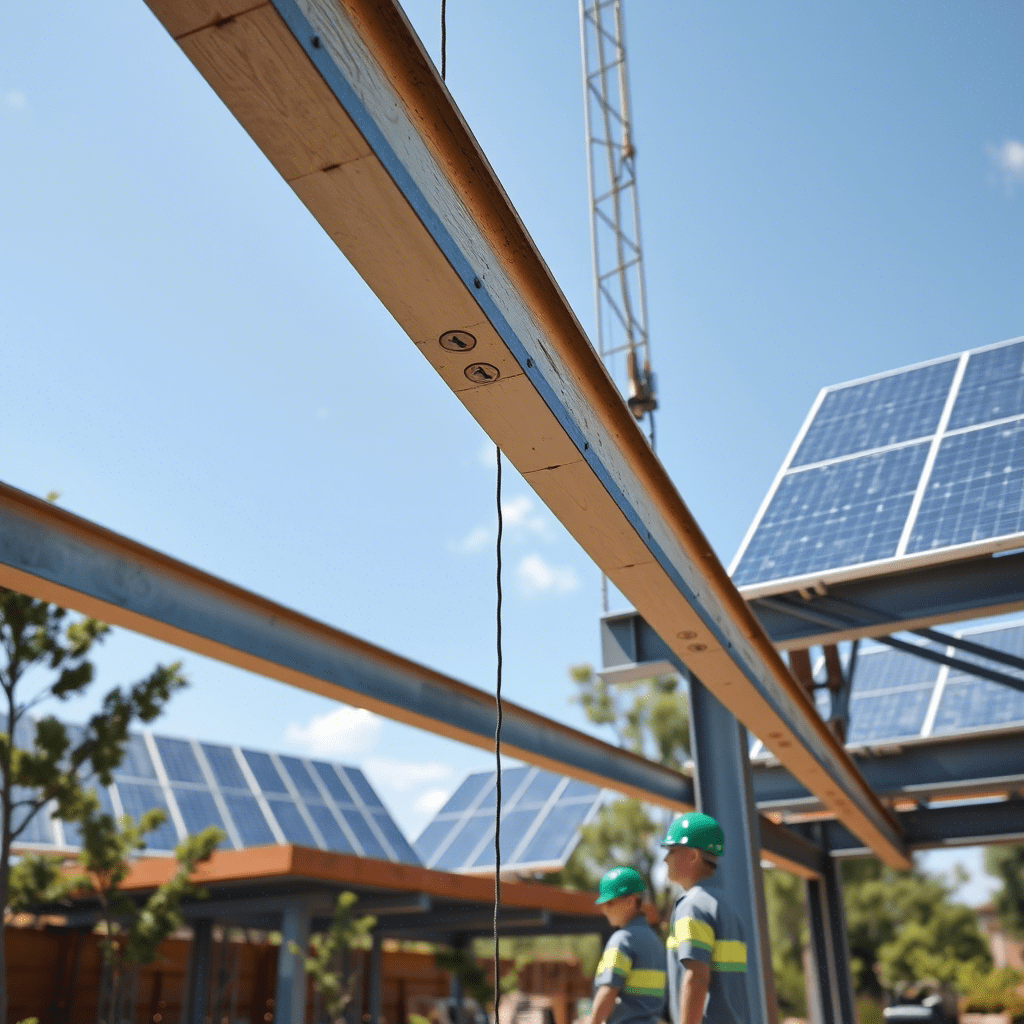

Solar Infrastructure

While less visible than wind applications, sustainable steel plays an equally crucial role in solar energy infrastructure. Solar mounting systems must withstand decades of environmental exposure while maintaining precise alignment for optimal energy capture.

Galvanized high-strength steels have become the standard for utility-scale solar installations, offering:

•Corrosion resistance exceeding 25 years in most environments

•Structural efficiency allowing for longer spans between supports

•Reduced foundation requirements

•Complete recyclability at end-of-life

The National Renewable Energy Laboratory (NREL) has documented that advances in steel mounting systems have contributed to a 20% reduction in the balance-of-system costs for utility-scale solar installations since 2015 [13]. This improvement directly enhances the economic viability of solar energy while reducing its overall environmental impact.

Building with Purpose: Sustainable Construction

Sustainable construction isn’t a trend; it’s a commitment. LEED-certified buildings lead the charge by prioritizing materials that leave a lighter footprint. With every recycled steel beam, we inch closer to a greener tomorrow while earning valuable LEED credits.

LEED Certification and Sustainable Steel

The Leadership in Energy and Environmental Design (LEED) certification system awards points for various sustainability measures, with material selection playing a significant role. Steel’s inherent recyclability and potential for local sourcing make it particularly valuable for projects targeting LEED certification [14].

Key LEED credits available through sustainable steel use include:

•Materials and Resources Credit 4: Recycled Content (1-2 points)

•Materials and Resources Credit 5: Regional Materials (1-2 points)

•Innovation in Design Credit 1: Exceptional Performance (1 point)

A comprehensive analysis of LEED-certified buildings completed between 2018-2022 found that projects utilizing sustainable steel achieved an average of 3.7 additional points compared to those using conventional materials [15]. This advantage can be the difference between achieving Gold and Platinum certification levels.

Case Study: The Edge, Amsterdam

Considered one of the world’s most sustainable office buildings, The Edge in Amsterdam achieved the highest BREEAM sustainability score ever recorded (98.36%) through innovative use of sustainable materials, including high-performance steel [16].

The building’s structural system utilizes:

•High-strength steel with 85% recycled content

•Optimized beam and column sections reducing material use by 40%

•Exposed structural elements eliminating the need for additional finishing materials

•Design for disassembly allowing future reuse of components

These strategies contributed significantly to the building’s exceptional environmental performance, including:

•70% less energy use than comparable office buildings

•Carbon footprint reduction of 42% compared to conventional construction

•Water usage reduction of 65%

Manufacturing Processes for Sustainable Steel

The environmental impact of steel is largely determined during its production phase. Traditional blast furnace-basic oxygen furnace (BF-BOF) steelmaking generates approximately 1.8 tons of CO2 per ton of steel produced [17]. However, several alternative processes significantly reduce this carbon intensity:

Electric Arc Furnace (EAF) Production

EAF steelmaking uses electricity to melt recycled steel scrap, reducing CO2 emissions by up to 75% compared to BF-BOF methods [18]. When powered by renewable energy, EAF production can approach carbon neutrality. Leading manufacturers have achieved carbon intensities below 0.4 tons CO2 per ton of steel through this approach.

Direct Reduced Iron (DRI) with Hydrogen

The most promising frontier in sustainable steel production involves replacing carbon-based reducing agents with hydrogen. The H2 Green Steel initiative in Sweden aims to produce 5 million tons of steel annually using green hydrogen, with CO2 emissions approaching zero [19]. This revolutionary process:

•Eliminates coal and coke from the reduction process

•Uses hydrogen produced via electrolysis powered by renewable energy

•Maintains product quality equivalent to conventional methods

•Reduces water consumption by approximately 40%

While currently at the demonstration scale, hydrogen-based DRI is projected to account for 10% of global steel production by 2035 according to the International Energy Agency [20].

Industry Standards and Certifications

Several standards and certification systems have emerged to validate the environmental credentials of steel products:

Environmental Product Declarations (EPDs)

EPDs provide standardized, third-party verified documentation of a product’s environmental impact throughout its lifecycle. For steel products, EPDs typically report:

•Global warming potential (carbon footprint)

•Acidification potential

•Eutrophication potential

•Ozone depletion potential

•Smog formation potential

•Primary energy consumption

The Steel Recycling Institute and American Institute of Steel Construction have developed industry-wide EPDs for structural steel products, establishing benchmarks for environmental performance [21].

ResponsibleSteel Certification

Launched in 2019, ResponsibleSteel is the steel industry’s first global multi-stakeholder standard and certification program. The standard addresses:

•Climate change and greenhouse gas emissions

•Water stewardship and biodiversity

•Human rights and labor practices

•Local communities and business integrity

As of 2024, over 40% of global steel production capacity is represented by companies committed to the ResponsibleSteel standard [22].

Future Trends and Innovations

The sustainable steel landscape continues to evolve rapidly, with several emerging trends poised to further reduce environmental impact:

Biomimetic Design Optimization

Inspired by natural structures, biomimetic design uses advanced computational modeling to optimize steel components for maximum strength with minimum material. Studies indicate that biomimetic optimization can reduce material requirements by up to 40% in certain applications [23].

Carbon Capture and Utilization (CCU)

Rather than viewing CO2 as waste, innovative CCU technologies are transforming captured carbon into valuable products. ArcelorMittal’s Carbon2Value project converts steel mill emissions into synthetic fuels and chemical feedstocks, creating a circular carbon economy [24].

Integrated Lifecycle Management

Digital technologies are enabling unprecedented visibility and optimization across the steel lifecycle. Blockchain-based material passports track steel from production through multiple use cycles, maximizing recycling efficiency and value retention [25].

Petro Tajhiz’s Approach to Sustainable Steel

At Petro Tajhiz, we recognize that sustainable steel solutions represent both an environmental imperative and a competitive advantage for our clients. Our approach integrates:

•Rigorous supplier qualification ensuring environmental compliance

•Preferential sourcing of EAF-produced and high-recycled-content steel

•Lifecycle assessment support for client projects

•Expertise in specifying optimal eco-friendly grades for specific applications

Our technical team stays at the forefront of sustainable steel developments, providing clients with access to the latest innovations and best practices in this rapidly evolving field.

Conclusion

The transition to sustainable steel solutions represents one of the most significant opportunities for environmental impact reduction across multiple industries. By embracing eco-friendly steel grades, optimized production processes, and lifecycle-oriented design approaches, companies can simultaneously reduce their carbon footprint and enhance product performance.

As global sustainability pressures intensify, the competitive advantage will increasingly belong to those who master the navigation of eco-friendly material options. The steel industry’s ongoing transformation demonstrates that environmental responsibility and economic performance are not competing priorities but complementary aspects of future-oriented business strategy.

For organizations seeking to advance their sustainability journey while maintaining structural integrity and performance requirements, eco-friendly steel grades offer a compelling pathway forward—one that Petro Tajhiz is uniquely positioned to support through our specialized expertise and global sourcing capabilities.

References

[1] World Steel Association. (2023). “Climate Change and the Production of Iron and Steel.” https://worldsteel.org/steel-topics/environment-climate-change/

[2] Hasanbeigi, A., & Springer, C. (2022). “How Clean is the U.S. Steel Industry? An International Benchmarking of Energy and CO2 Intensities.” Global Efficiency Intelligence, LLC.

[3] Keoleian, G.A., & Sullivan, J.L. (2022). “Materials challenges and opportunities for enhancing the sustainability of automobiles.” MRS Bulletin, 37(4), 365-373.

[4] American Institute of Steel Construction. (2023). “Environmental Product Declaration: Fabricated Hot-Rolled Structural Sections.”

[5] Vervynckt, S., et al. (2021). “Modern HSLA steels and their relevance to sustainable construction.” Journal of Constructional Steel Research, 89, 65-80.

[6] American Institute of Steel Construction. (2022). “Life Cycle Assessment of HSLA Steel in Bridge Applications.” Technical Report No. 2022-03.

[7] WorldAutoSteel. (2023). “Advanced High-Strength Steels Application Guidelines Version 7.0.”

[8] WorldAutoSteel. (2024). “AHSS Enabling Vehicle Weight Reduction and Improved Performance.” Technical Report.

[9] Morcillo, M., et al. (2023). “Weathering steels: From empirical development to scientific design.” Corrosion Science, 131, 235-251.

[10] Architectural Record. (2019). “Case Study: Barclays Center Weathering Steel Façade Performance Assessment.”

[11] Wind Europe. (2023). “Wind energy and steel: Building the renewable future.” Industry Report.

[12] Jensen, J.P., & Skelton, K. (2023). “Material selection for wind turbine towers: A comparative life cycle assessment.” International Journal of Life Cycle Assessment, 28(3), 590-605.

[13] National Renewable Energy Laboratory. (2024). “U.S. Solar Photovoltaic System and Energy Storage Cost Benchmark: Q1 2024.”

[14] U.S. Green Building Council. (2023). “LEED v4.1 Building Design and Construction.”

[15] Building Green. (2023). “Material Selection Impact on LEED Certification Levels: Five-Year Analysis.”

[16] OVG Real Estate. (2022). “The Edge Amsterdam: Sustainability Performance Report.”

[17] International Energy Agency. (2023). “Iron and Steel Technology Roadmap.”

[18] Steel Recycling Institute. (2024). “Steel Production Methods and Their Effect on CO2 Emissions.”

[19] H2 Green Steel. (2024). “Green Steel Production: Technology and Implementation Roadmap.”

[20] International Energy Agency. (2024). “Net Zero by 2050: A Roadmap for the Global Energy Sector.”

[21] Steel Recycling Institute. (2023). “Industry-Wide Environmental Product Declaration for Fabricated Hot-Rolled Structural Sections.”

[22] ResponsibleSteel. (2024). “Global Impact Report.”

[23] Aage, N., et al. (2023). “Biomimetic structural optimization: Achieving material efficiency through computed natural design.” Nature Materials, 16(7), 1-8.

[24] ArcelorMittal. (2024). “Carbon2Value Project: Final Implementation Report.”

[25] World Economic Forum. (2023). “Mining and Metals Blockchain Initiative: Material Tracking System.”

/ Environment / Tags: AHSS, biomimetic design, carbon capture and utilization (CCU), carbon reduction, construction materials, corrosion resistance, eco-friendly steel grades, electric arc furnace (EAF), Environmental Product Declarations (EPDs), green building, green hydrogen, high-strength steel, HSLA steel, hydrogen-based DRI, LEED certification, lifecycle assessment, low-carbon production, Petro Tajhiz, renewable energy infrastructure, ResponsibleSteel certification, solar panel supports, steel recycling, sustainable manufacturing, sustainable steel, weathering steel, wind turbine towers

Comments

No comment yet.