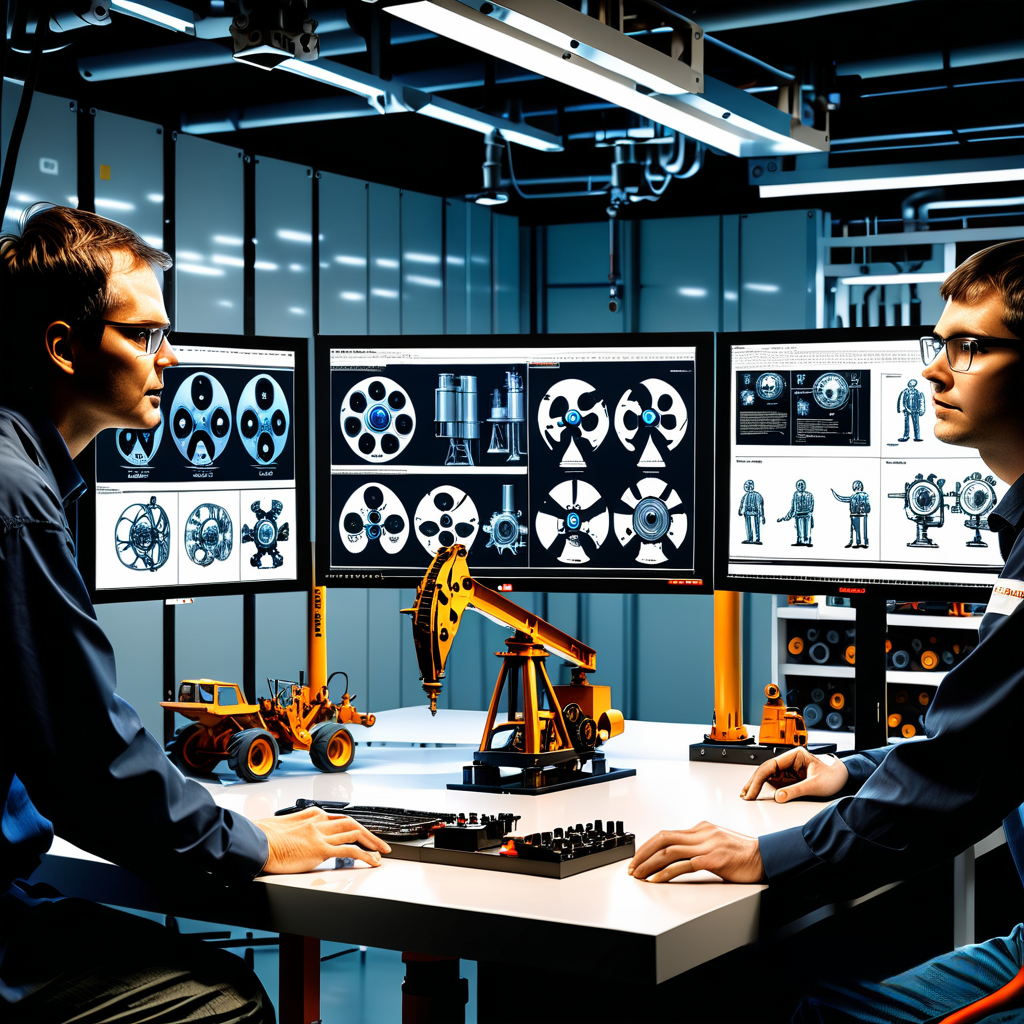

AI-driven design improvements for oil well tools enhance efficiency, precision, and durability, optimizing drilling operations. By leveraging machine learning algorithms, these tools adapt to various geological conditions, minimizing downtime and maximizing production output. Through continuous data analysis, AI enables predictive maintenance, ensuring optimal performance and longevity of equipment in challenging oil field environments.

AI-Driven Design Improvements for Oil Well Tools

The oil and gas industry relies heavily on specialized tools and equipment for efficient exploration, drilling, and production operations. In this proposal, we advocate for the integration of artificial intelligence (AI) into the design process of oil well tools, aiming to enhance functionality, reliability, and performance.

Objective:

The primary objective of this proposal is to leverage AI technology to drive design improvements in oil well tools, leading to enhanced efficiency, durability, and cost-effectiveness. By integrating AI into the design process, our goals include:

- Enhancing tool functionality to address specific operational challenges and requirements.

- Improving tool reliability through predictive analytics and performance optimization.

- Optimizing tool performance to increase productivity and minimize downtime.

- Reducing design iteration cycles and time-to-market for new oil well tools.

Implementation Plan:

- Data Collection and Analysis: Gather data from various sources, including historical performance data, engineering specifications, and operational requirements. Analyze this data to identify patterns, trends, and opportunities for design improvements.

- Machine Learning Algorithms: Develop machine learning algorithms trained on historical data to predict tool performance under different operating conditions. These algorithms will be used to optimize tool designs and identify potential failure modes.

- Design Optimization: Utilize AI-driven optimization techniques to iteratively improve tool designs, taking into account factors such as material properties, structural integrity, and manufacturing constraints. This process will involve simulation-based design exploration to identify the most promising design configurations.

- Validation and Testing: Validate AI-generated designs through virtual simulations and physical prototyping. Conduct rigorous testing to verify performance, reliability, and durability under real-world operating conditions.

- Integration with CAD Software: Integrate AI-driven design optimization algorithms with computer-aided design (CAD) software tools used by engineers. This integration will enable seamless generation and evaluation of AI-enhanced tool designs within existing design workflows.

Expected Outcomes:

- Enhanced Functionality: AI-driven design improvements will result in oil well tools that are better tailored to specific operational requirements, leading to improved performance and efficiency.

- Improved Reliability: Predictive analytics and optimization techniques will enhance tool reliability by identifying and mitigating potential failure modes before they occur.

- Increased Performance: Optimized tool designs will enable higher productivity and reduced downtime, ultimately leading to cost savings and improved operational efficiency.

- Accelerated Design Process: By automating design optimization tasks, AI will reduce design iteration cycles and time-to-market for new oil well tools, enabling faster innovation and adaptation to changing operational needs.

Conclusion:

The integration of AI into the design process of oil well tools represents a significant opportunity to drive innovation and efficiency in the oil and gas industry. By leveraging AI-driven design improvements, companies can develop tools that are more reliable, performant, and cost-effective, ultimately enhancing their competitive edge in the market. Collaboration with AI experts, engineering teams, and industry stakeholders will be essential in realizing the full potential of AI in oil well tool design.

Comments

No comment yet.